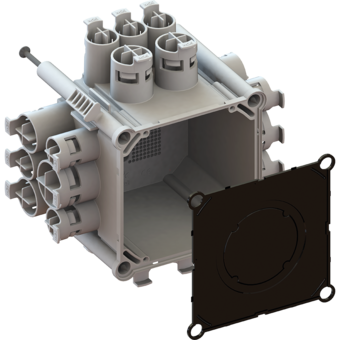

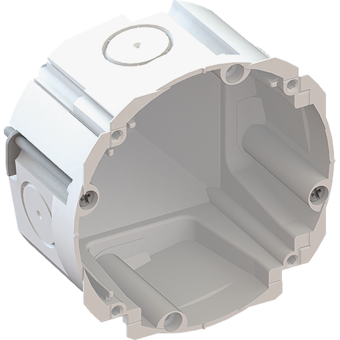

Mini equipment carrier

Mini equipment carrier with 4 swivels and 2 ribs

- Article no: 1159-50

- E no.: 165372008

- EAN: 4013456536197

- Retrofitting in existing composite thermal insulation systems (ETICS)

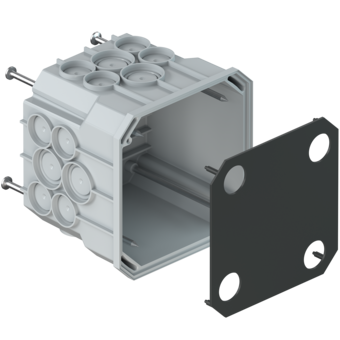

- consisting of anchor sleeve and attachment core

- for insulation thicknesses of 80 mm and upwards

- Screw-on surface with 10 mm tolerance compensation

- 4 swivel cutters

- 2 ribs

- Sealing lip on all sides

- Weight loading up to 30 N (3 kg)

- equipment attached with self-tapping screws with Ø of 3.2 - 4 mm

Mini equipment carrier

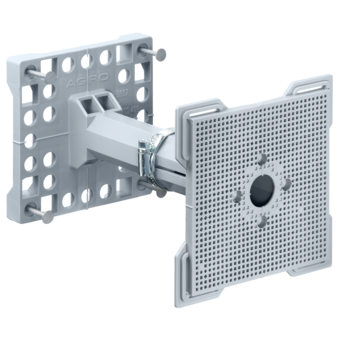

Mini equipment carrier for later attachment of a variety of accessories to insulated and already plastered composite thermal insulation systems. Luminaires, motion detectors, external sensors etc. can be permanently attached easily, quickly, securely and without creating heat bridges.

- For retrofitting in insulated facades

- Exact flush aligning of attachment devices

- Guarantees installation without heat bridges

- 4 swivels for secure anchoring

- No moisture penetration

Examples of use

Technical information

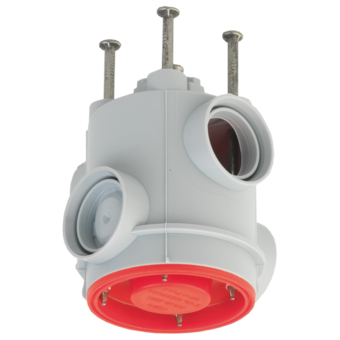

SPECIAL cutter Ø 20 x 80 mm for KAISER mini equipment carrier

Structure of an organic ETICS

The mini equipment carrier was developed especially for later installation in organic composite thermal insulation systems (ETICS).

1 Masonry wall | 2 Adhesive | 3 Insulating board | 4 Reinforcement plaster | 5 Reinforcement fabric | 6 Reinforcement plaster | 7 Finish coat of plaster, decorative plaster

Maximum pull-out force for the mini equipment carrier.

1 External insulation - insulation thickness

Heat bridge calculation

A heat bridge analysis produced by the Passivhaus Institut Dr. Feist, Darmstadt, showed that heat conductivity is only changed to a negligible extent and consequently it is demonstrated that there are no heat bridges in the electrical installation. The loss coefficient "× WB" is 0.000054 W/K.

Installation

The two-piece mini equipment carrier can be anchored securely in the insulated external facade in a few simple steps.