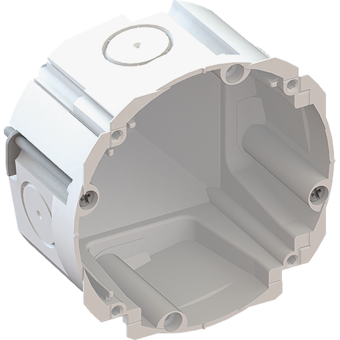

Box sealing system DS 90 / 120 mm

Box sealing system DS 90 / 120 mm

- Article no: 9459-04

- E no.: 121819018

- EAN: 4013456537156

- for EI90 fire-protection walls

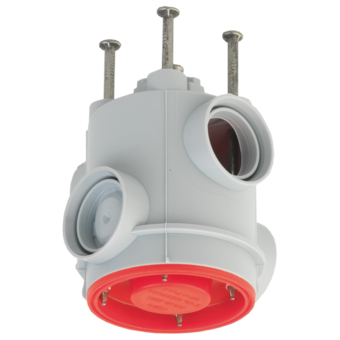

- attachment using tried-and-tested FX⁴ metal plate screws

- with integrated sealing inserts

- ensures smoke-tight room separation (seals against cold smoke)

- unlimited building material shelf life

Box sealing system DS 90 / 120 mm

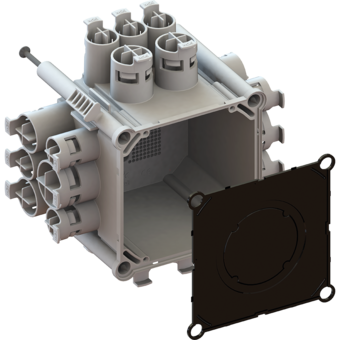

The new box sealing system DS 90 / 120 mm covers an additional range of applications in building fire protection. The increased diameter makes it possible to use a larger number of cables and electrical installation conduits and also greater diameters. With this system, it is also possible to mix the installation of conduits and cables. In addition, full population, as with the DS 90 / 74 mm, allows use of the system in all fields of building technology. Because no additional materials are used, non-destructive retrofitting is also possible. The tried-and-tested screw fixing permits clean, safe and secure installation.

- Secure, visible, certified fire sealings

- Seals wall feed-throughs

- Automatic sealing of the joints and gaps between cables - no filling and smoothing

- Non-destructive retrofitting

- Also for mixed population of bundles of cables and conduits

Examples of use

Technical information DS 90 / 120 mm

Population of box sealing system DS 90 / 120 mm

Installation

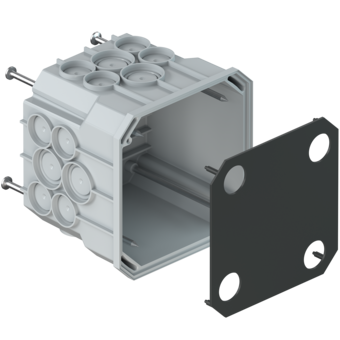

The box sealing system DS 90 / 120 consists of two parts which easily fit together.

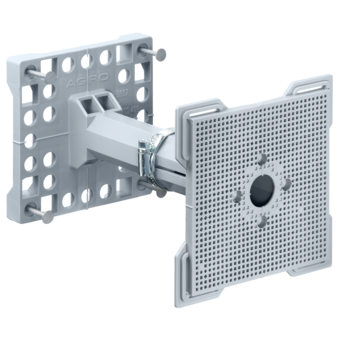

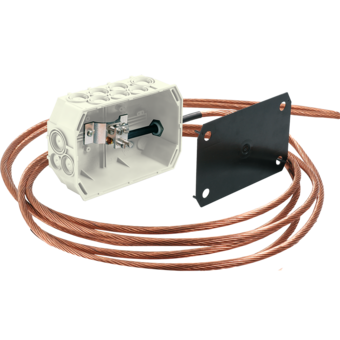

Non-destructive retrofitting of single cables and conduits

Installation of box sealing system DS 90 / 120 mm in masonry

Installation of box sealing system DS 90 / 120 mm in concrete walls

Table of max. external diameter of sheathed cables (NYM cables)

The table shows examples of cables which can be used on the basis of the maximum permitted diameter. The main factor is the minimum stated standard diameter acc. to DIN VDE 0250-204.

Two box sealing systems DS 90 / 120 are required feed-throughs in a fire-protection wall.

Examples of use

Technical information DS 90 / 120 mm

Population of box sealing system DS 90 / 120 mm

Installation

The box sealing system DS 90 / 120 consists of two parts which easily fit together.

Non-destructive retrofitting of single cables and conduits

Installation of box sealing system DS 90 / 120 mm in masonry

Installation of box sealing system DS 90 / 120 mm in concrete walls

Table of max. external diameter of sheathed cables (NYM cables)

The table shows examples of cables which can be used on the basis of the maximum permitted diameter. The main factor is the minimum stated standard diameter acc. to DIN VDE 0250-204.

Two box sealing systems DS 90 / 120 are required feed-throughs in a fire-protection wall.