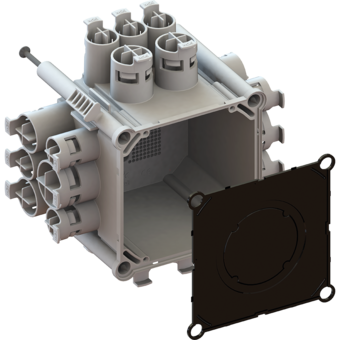

HaloX® concrete installation housing (on-site mixed concrete)

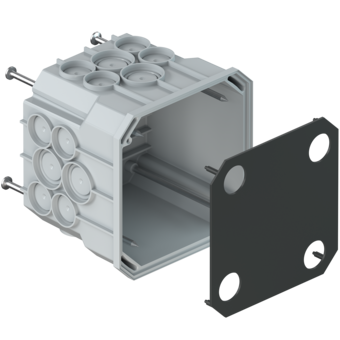

HaloX® 250 front parts

- Article no: 1283-05

- E no.: 920896549

- EAN: 4013456547209

- Suitable for housings with Art. No. 1283-XX

HaloX® concrete installation housing (on-site mixed concrete)

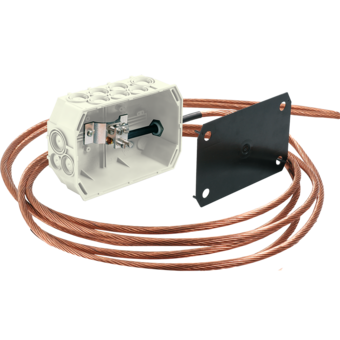

The shape-retaining HaloX® system has a modular design for fitting in on-site mixed concrete. Three housing diameters with a large number of round, square and universal front parts allow the integration of luminaires and loudspeakers up to an installation diameter of 250 mm, including in facing concrete. With a tunnel, the system provides sufficient space for operating devices, such as LED drivers. Optional extension rings to increase the installation depth. All front parts are moisture-repellent and can be positioned exactly and nailed-on even before the first reinforcement is laid. Housings and front parts are firmly and stably latched together and can still be aligned as required afterwards. By means of the toolless, opening technology with a M20/M25 combination entry, conduits can be inserted quickly and easily and, even if the population is incorrect, the entry can easily be closed again. It provides secure conduit retention with a depth stop, so there is no need for subsequent internal shortening of the conduits. After casting, front parts with a defined installation diameter can be opened with a targeted blow of the hammer. The front parts for universal opening sizes can be plastered locally or plastered over. You can then cut the required installation opening using standard cutting tools e.g. PROFI cutter.

- For walls and ceilings

- Housings and front parts are latched together securely and sturdily, and can also be subsequently aligned as required

- All housing sizes are available with and without a tunnel

- Toolless entry technology for M20/M25 conduits

- Optimal heat management thanks to maximum surface contact with the concrete

- Minimal impact on the main structure – does not require reinforcement steel to be cut to create the tunnel

Examples of use

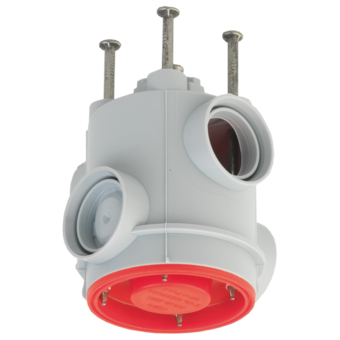

Installation on the ceiling formwork

Wall installation, installation on the working formwork

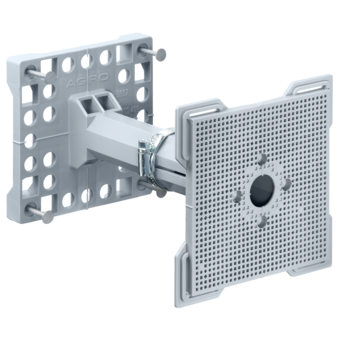

Wall mounting, mounting to the opposing formwork side using the Prefix® installation set

Extension rings

Extension rings are available to enlarge the installation compartment.