FlamoX® fire-protection putty

FlamoX® fire-protection putty

FlamoX® fire-protection putty

- Article no: 9400-05

- E no.: 920898009

- EAN: 4013456461611

- Building material forming an insulating layer

- for filling joints as well as bonding board materials

- Type 9400

- Working time 30 mins.

- Can be stored up to 12 months

DIBt approval

Z-19.11-1583

Contents

300 ml

Dispatch

20

Product information

FlamoX® fire-protection putty

Fireproof sealing of joints and expansion joints. Filling of gaps in fire protection systems and for cable penetration seals according to DIN 4102, part 9. The mastic is in building material class DIN 4102-B2 and is free of asbestos and solvents.

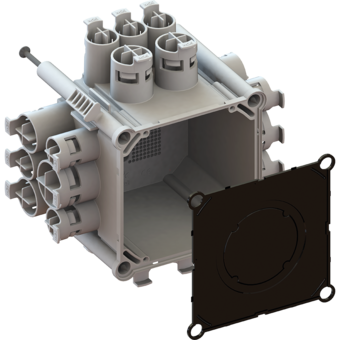

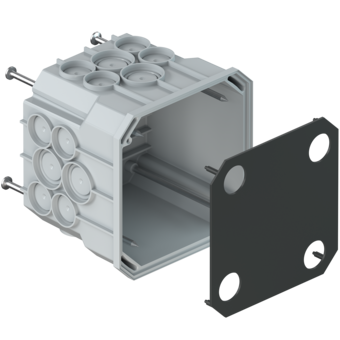

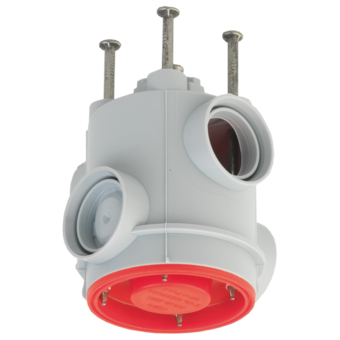

- Fire protection housing system for luminaires and loudspeakers

- For single or double layer suspended EI30 fire protection hollow ceilings

- Fire resistance from above and below

- Intelligent, automatic sealing

- Smokeproof and halogen-free

- For new build or as a fire protection upgrade in existing buildings

- DIBt approval Z-19.11-1583

- Contact surfaces must be clean, dry and free of grease

- Ambient temperature and temperature of the materials to be coated should be ≥ 10°C

- For indoor use only

Shelf life

12 months / observe date of manufacture!

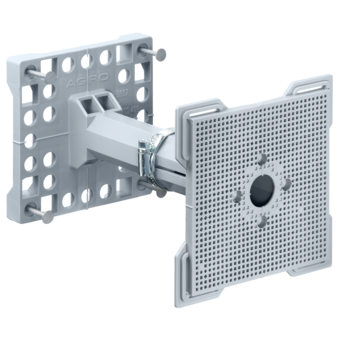

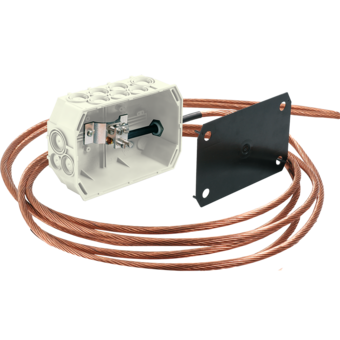

Retrofitting in installation shafts

The HWD 90 cavity wall boxes can also be retrofitted in installation shafts (shaft walls). Since retrofitting partly requires adding mineral wool to the opening, a cut-out of at least 300 x 300 mm is needed to make space for perfect installation. Use the following cut-out dimensions for the relevant combinations:

- 1-time: 300 x 300 mm

- 2 to 3-times: 300 x 400 mm

- 4 to 5 times: 300 x 600 mm

Download